General context

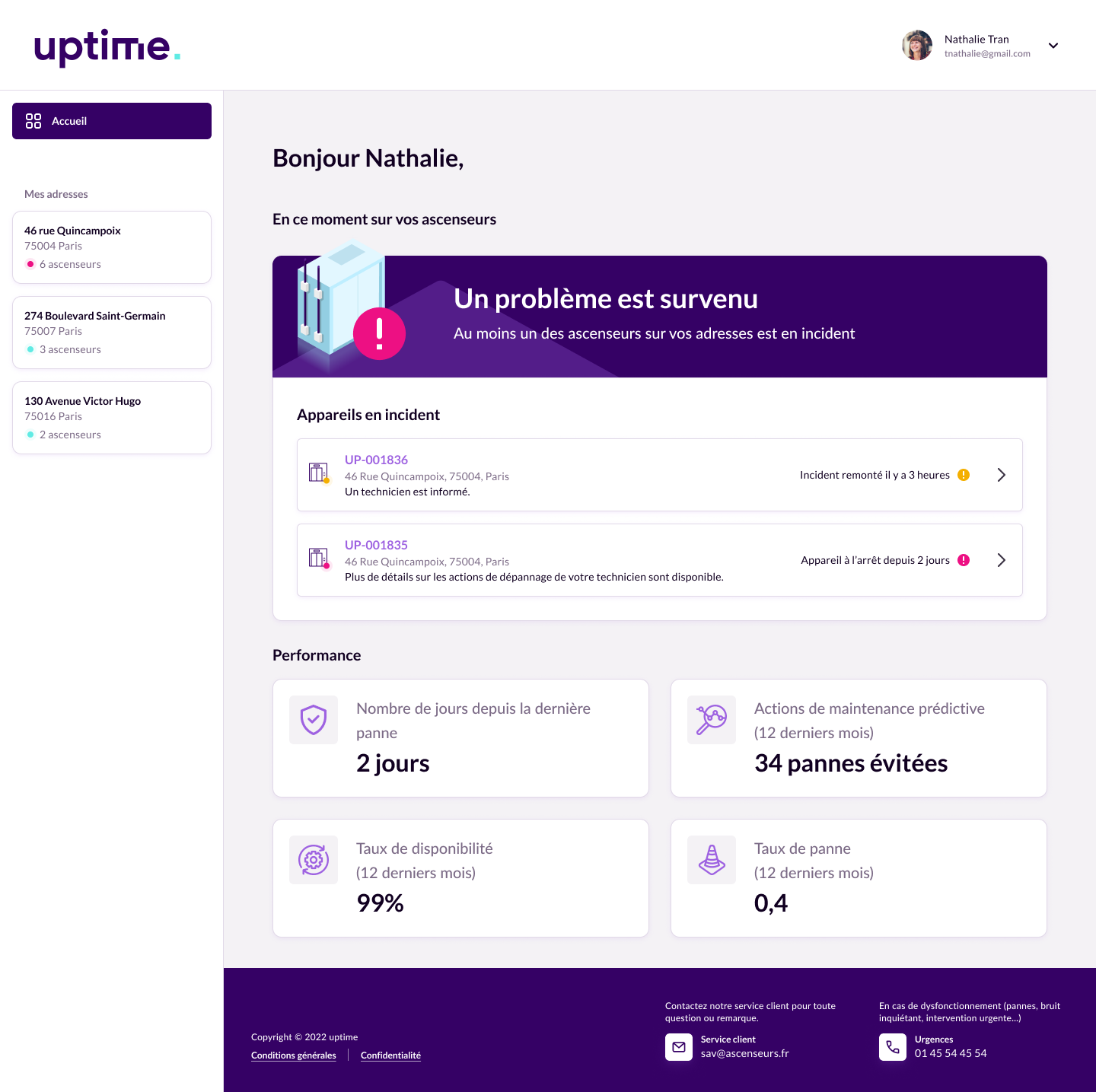

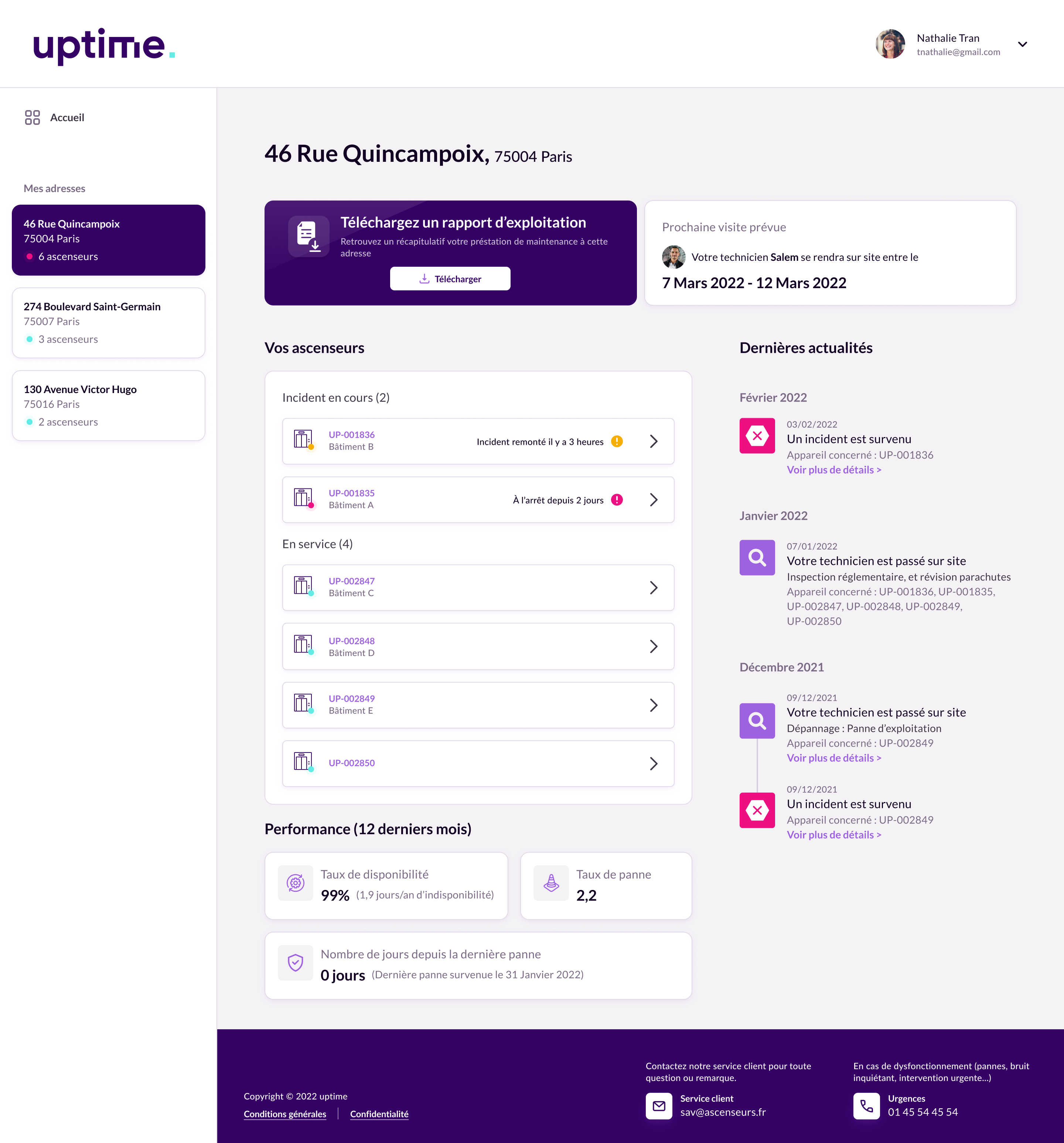

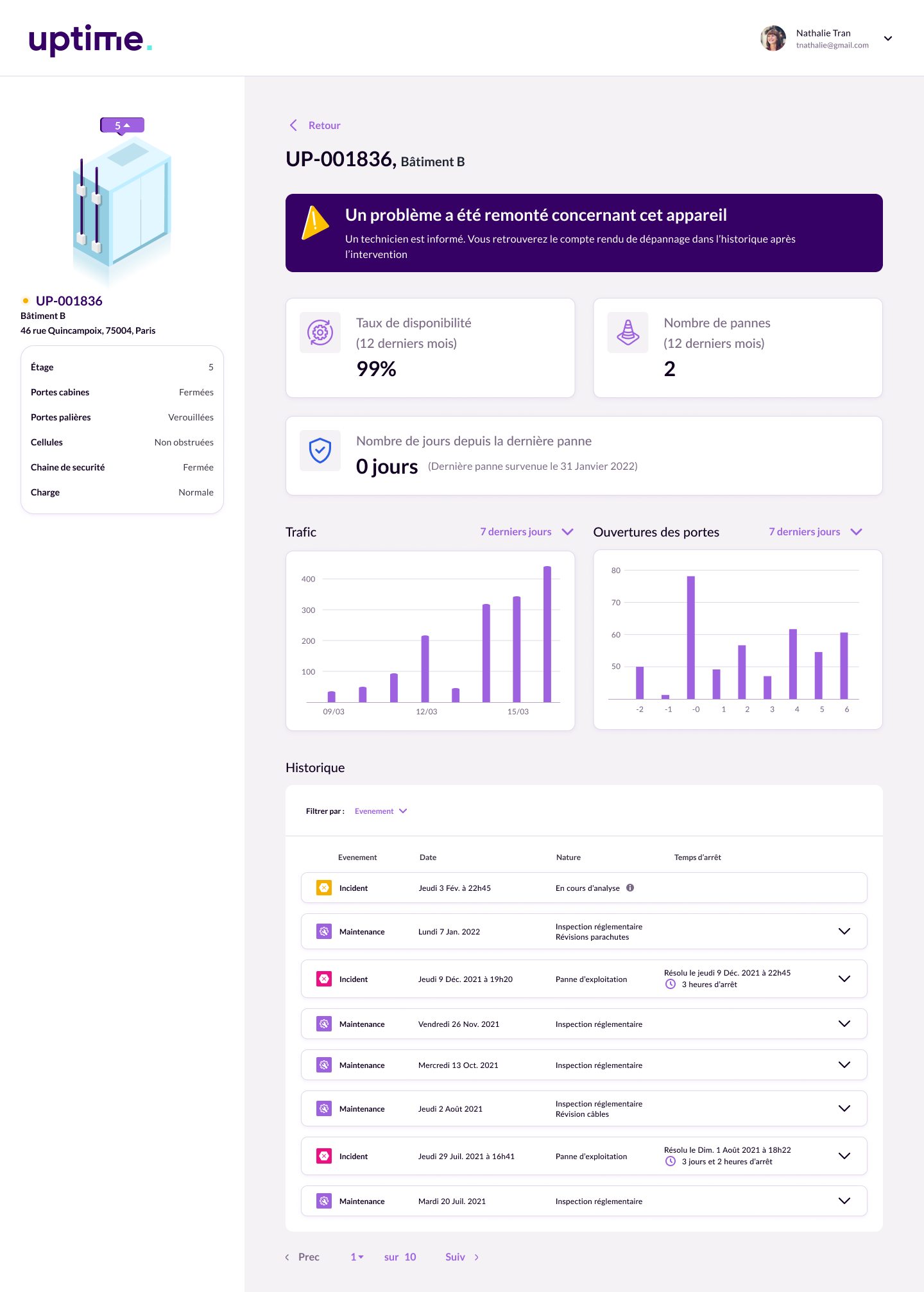

This project is named after Uptime, a lift maintenance company that prides itself on predictive maintenance. Each lift, no matter the manufacturer or the model, has a great amount of sensors for monitoring the state of the lift at all times (going from simple information like “the doors opened at 3:35PM on floor 6” all the way to minute details about components malfunctioning or any anomaly of the sort). All that information is relayed to the motherboard of the lift for later consultation by a lift maintenance engineer.

Normally, a lift maintenance engineer comes to the site of a broken down lift, accesses that stored info and figures out the next steps from there. Uptime however has developed a connected device, plugged at all times into the lift’s motherboard and connected to a 4G antenna, that allows lift engineers to access that data and know what is going on with a lift from their smartphone without having to physically move there to check.

This allows lift maintenance engineers to optimise their breakdown interventions. Or even better: through pattern detection algorithms, possible breakdowns can be detected before they can happen and be prevented.

After developing that device and successfully using it for their own maintenance operation, uptime started renting their technology to other lift maintenance SMBs, in order to democratise predictive maintenance.